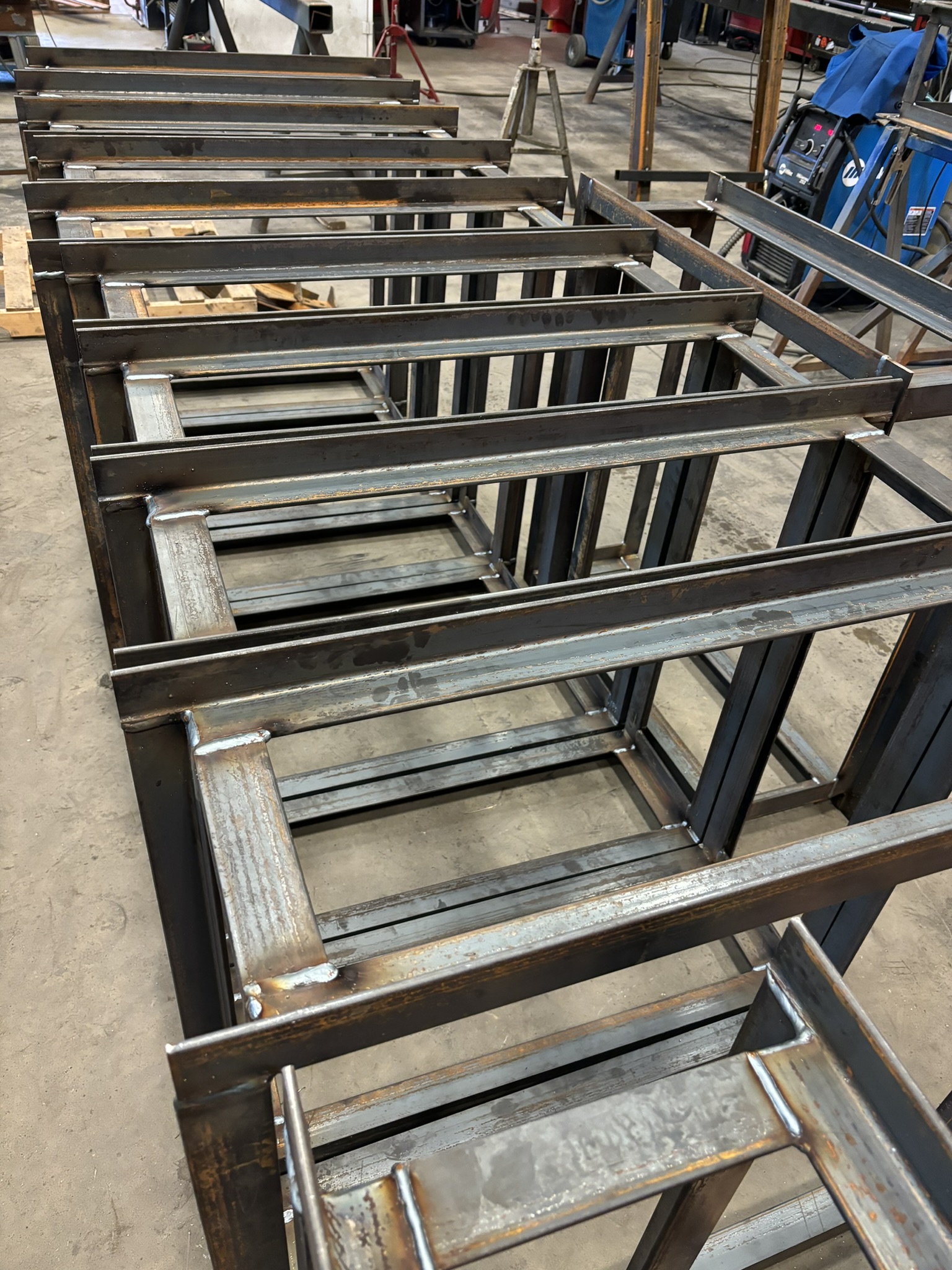

Radon Cages

Custom Fabrication

Custom designed radon gas capture cages for buildings, fabricated efficiently to meet high demand with durable hot-coat galvanizing.

Project Overview

These radon cages were custom designed by our client for installation under concrete slabs in buildings, basements, and parking garages. Their purpose is to capture radon gas, which can impact health and well-being. The cages come in three sizes, tailored to the building's size and scope. 4E Welding & Design Inc. fabricates these cages from client-provided drawings, using sheet metal, screen, and structural steel. After welding, the cages are hot-coat galvanized for durability.

This project highlights 4E’s ability to meet specific client requirements and ensure the functionality and safety of custom-designed components.

Challenges & Solutions

Fabricating radon cages is a high-production task, making efficiency crucial. The team optimized the fabrication process to ensure consistent quality and timely delivery. Managing the timeline from start to the completed galvanized part was essential due to the high demand for these cages. 4E Welding & Design Inc.’s ability to streamline production and maintain strict timelines ensured they met the client's needs effectively.