Land Rollers

Agriculture

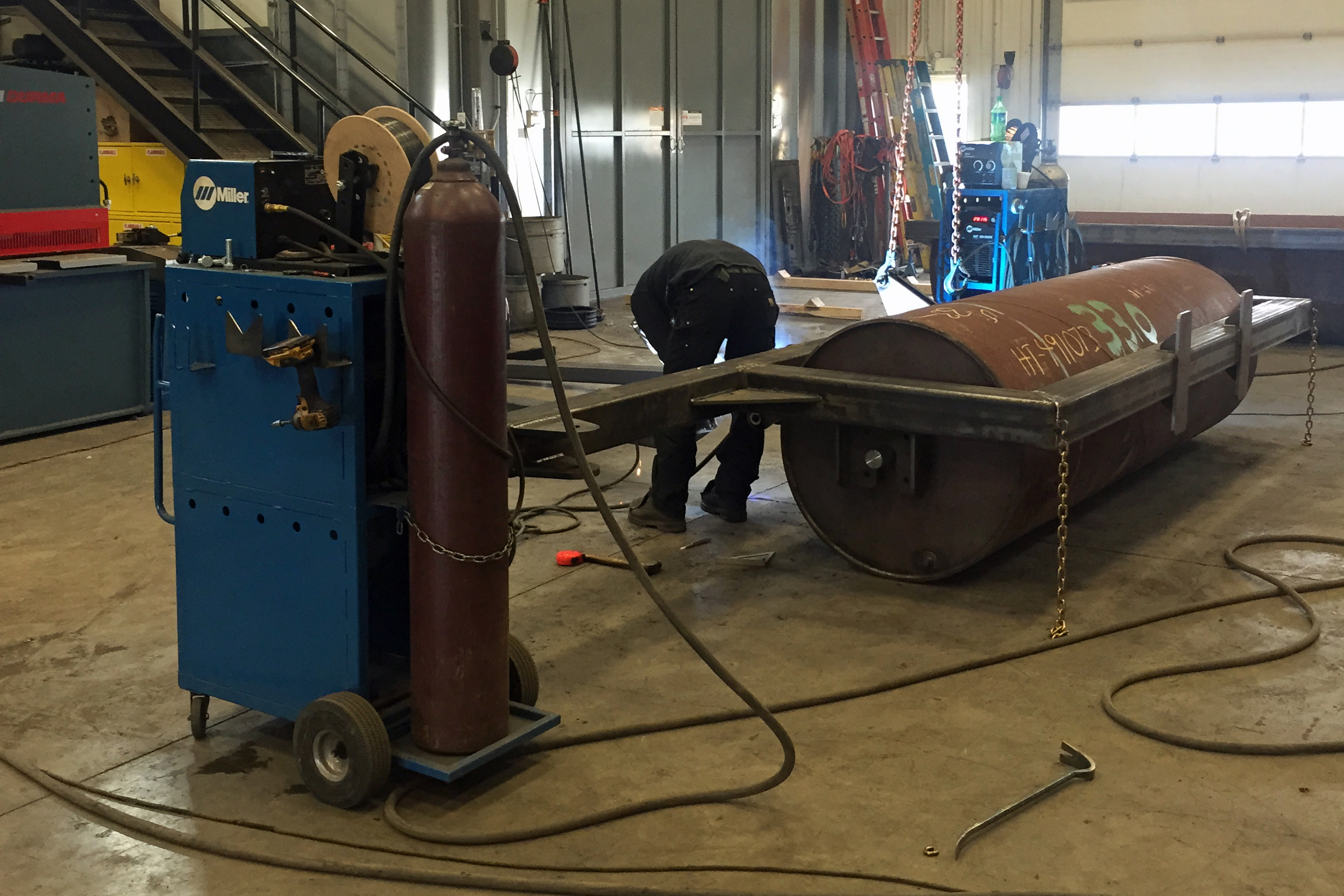

Custom designed and fabricated rollers for post-seeding ground flattening, featuring unique sizes and modular design for flexible agricultural use.

Project Overview

4E Welding & Design Inc. was commissioned to design and fabricate a custom set of rollers for flattening ground and pushing down rocks after springtime seeding. Unlike standard options available from equipment suppliers, the customer required unique sizes. The design aimed for simplicity, allowing multiple rollers to be linked for larger coverage or used individually. Materials were sourced locally, using 36” heavy wall pipe and structural steels, ensuring durability and performance.

The project showcases 4E Welding & Design Inc.’s ability to tailor agricultural equipment to meet specific client needs, providing robust and efficient solutions that enhance farming operations.

Challenges & Solutions

The primary challenge was working with the large size and diameter of the pipes, which differed from typical projects. The fabrication process required precise handling and welding techniques to ensure structural integrity and performance. Additionally, transporting the fabricated rollers posed logistical challenges, given their size and weight. To address this, 4E Welding & Design Inc. coordinated with transportation services to secure the necessary equipment and permits for safe delivery. Despite these hurdles, the team’s expertise and meticulous planning ensured the successful completion and delivery of the project.