Drilling Rigs

Commercial Drilling

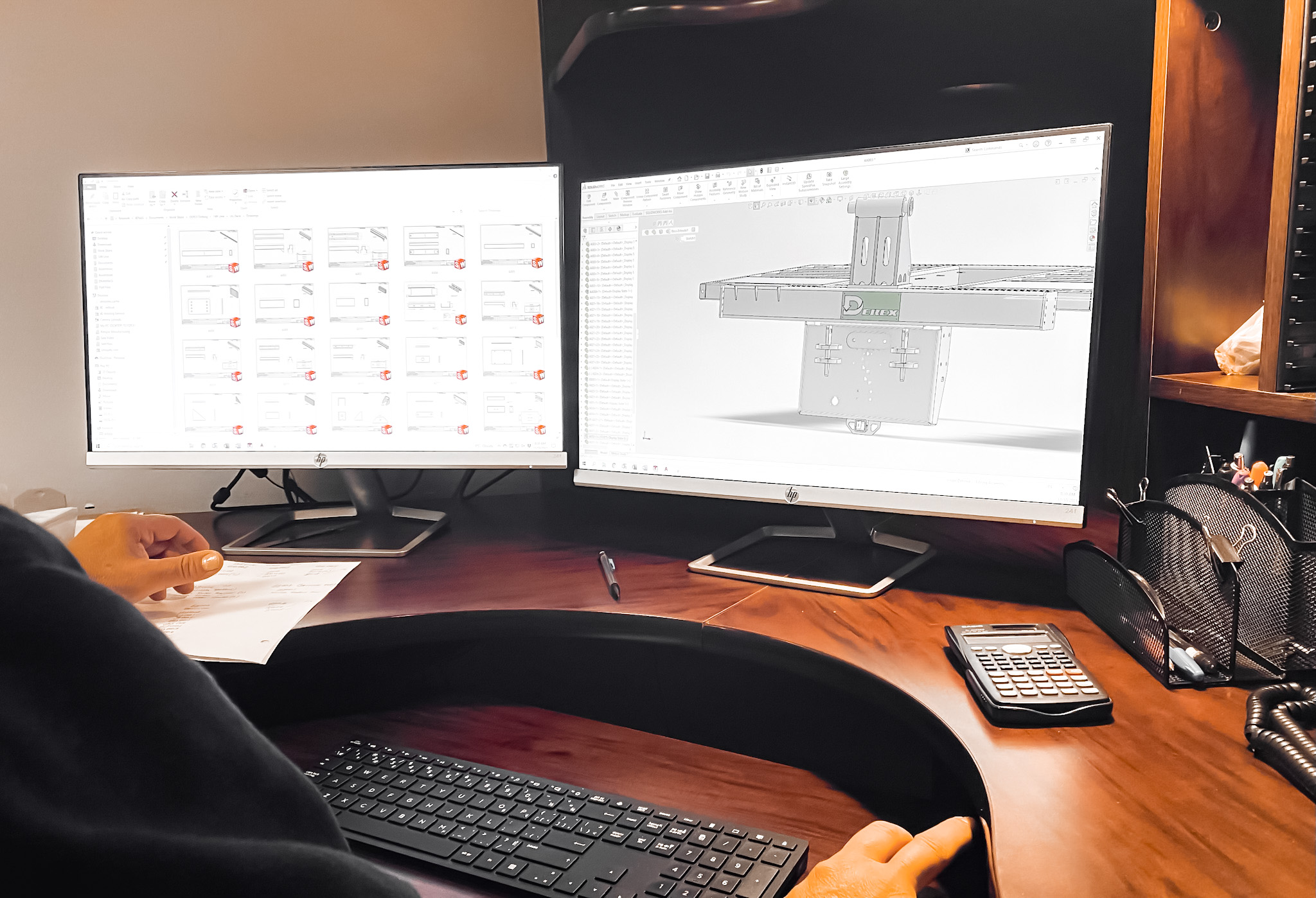

Custom designed drilling rigs built for tight spaces, shipped across North America, showcasing 4E Welding & Design Inc.'s fabrication and welding expertise.

Project Overview

4E Welding & Design Inc. has built a strong relationship with a local company over the last five years, collaboratively designing a fleet of custom drilling rigs. These rigs are specifically built to fit into tight spaces and are shipped all over North America. The project has been rewarding for 4E for several reasons: working with a local company, building a lasting partnership, contributing to the customer's success story, and seeing these rigs become a high-volume product. This project utilizes 4E’s extensive design, fabrication, and welding tools, giving their customer a competitive advantage.

The drilling rigs not only meet specific spatial constraints but also showcase the capabilities of 4E Welding & Design Inc. in custom fabrication. The continuous production cycle, where one rig is completed as the next begins, underscores the high demand and efficiency of their process.

Challenges & Solutions

The earlier builds of these units were research and development (R&D) intensive, with many components undergoing several revisions. Each iteration aimed to enhance performance, durability, and adaptability to various drilling environments. To address these challenges, 4E Welding & Design Inc. focused on continuous improvement and close collaboration with the client, ensuring that each new version met the evolving needs of the industry. This iterative process has resulted in a refined product that is now a staple in the client's fleet.