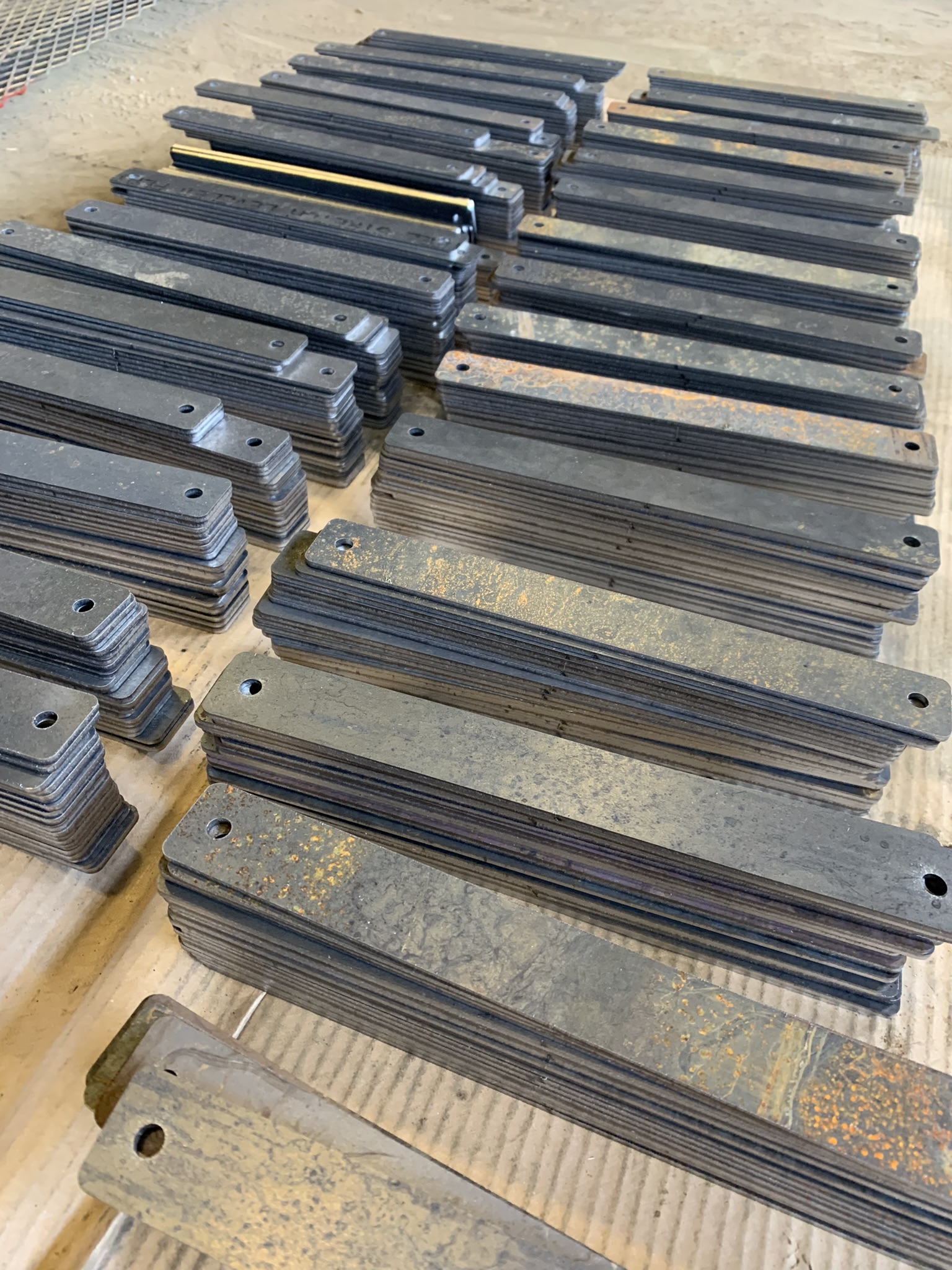

Custom Processing Packages

Fabrication

Comprehensive handling of processing packages from drawing files to final QC inspection, showcasing precision in custom fabrication.

Project Overview

4E Welding & Design Inc. excels in handling custom processing packages provided by clients, which include detailed drawings and cut files. Our team meticulously manages the entire process, from ordering the necessary materials to creating quality control (QC) spreadsheets and providing essential information to the shop floor. The skilled shop team cuts and forms parts based on the provided drawings, conducts thorough QC inspections, and ensures the parts are properly packaged for delivery to the customer.

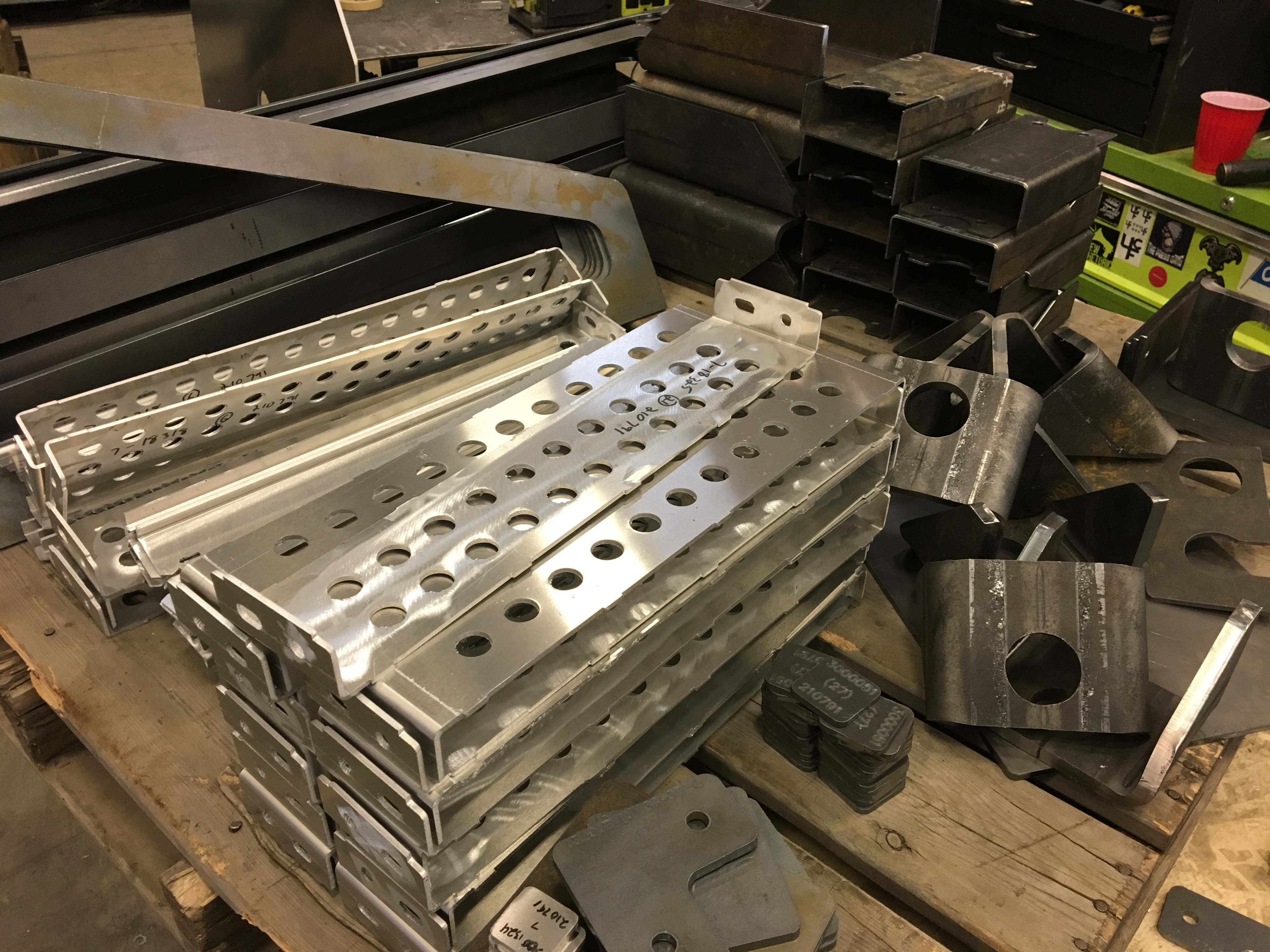

Challenges & Solutions

Handling custom processing packages presents several challenges that our team expertly navigates. Managing complex bend profiles requires the correct tooling to achieve precise bends, ensuring each part matches the design specifications. To align cut files accurately with related drawing files, we implement a robust QC process, minimizing errors and ensuring consistency.

Proper file scaling and dimensioning are critical, and we address this by organizing files and ordering the correct materials before starting the project. Additionally, providing specific material types can be challenging, but we maintain an extensive inventory of diverse materials to meet various requirements. By addressing these challenges head-on, 4E Welding & Design Inc. upholds its reputation for delivering high-quality, custom-fabricated parts on time and to exact specifications.