The Benefits of Custom Metal Work for Your Business

Unlock the advantages of custom metal work. Tailored solutions, enhanced durability, and cost-effectiveness can elevate your business operations.

Published on

8 Aug 2024

In the competitive world of business, the ability to tailor solutions to meet unique needs is invaluable. Custom metal work offers businesses the flexibility to design and fabricate components that precisely fit their specific requirements. This blog post will delve into the numerous benefits of custom metal work and how it can enhance various aspects of your business operations.

Tailored Solutions to Meet Specific Needs

Customization and Flexibility

Custom metal work provides unparalleled customization and flexibility. Unlike off-the-shelf products, custom metal components are designed and fabricated to meet exact specifications. This ensures that every part and structure fits perfectly within its intended application, leading to better performance and efficiency. For example, 4E Welding & Design Inc. specializes in creating custom metal structures that cater to the unique demands of each project, whether it’s a complex industrial machine part or an intricate architectural element.

Adaptability

One of the standout benefits of custom metal work is its adaptability. Businesses can adjust designs and specifications based on evolving needs and new challenges. This adaptability is crucial in industries where standards and technologies are continually changing. Custom metal fabrication allows businesses to stay ahead of the curve, ensuring their equipment and structures are always up to date.

Custom metal work's adaptability also extends to various industries, such as automotive, aerospace, and construction. In the automotive industry, for instance, custom metal parts can be designed to enhance vehicle performance and aesthetics, accommodating unique design requirements and technological advancements. Similarly, in aerospace, precision and customization are paramount to ensuring safety and performance standards.

Enhanced Durability and Quality

High-Quality Materials

Custom metal work often involves the use of superior materials tailored to specific applications. This choice of high-quality materials ensures that the final product is robust and reliable. 4E Welding & Design Inc. utilizes top-grade metals and alloys, ensuring that every custom component meets stringent quality standards.

Using high-quality materials not only enhances the durability of the components but also improves their resistance to wear and tear. For example, in environments where corrosion resistance is essential, stainless steel or aluminum alloys might be selected. This ensures that the components will last longer and perform better under challenging conditions.

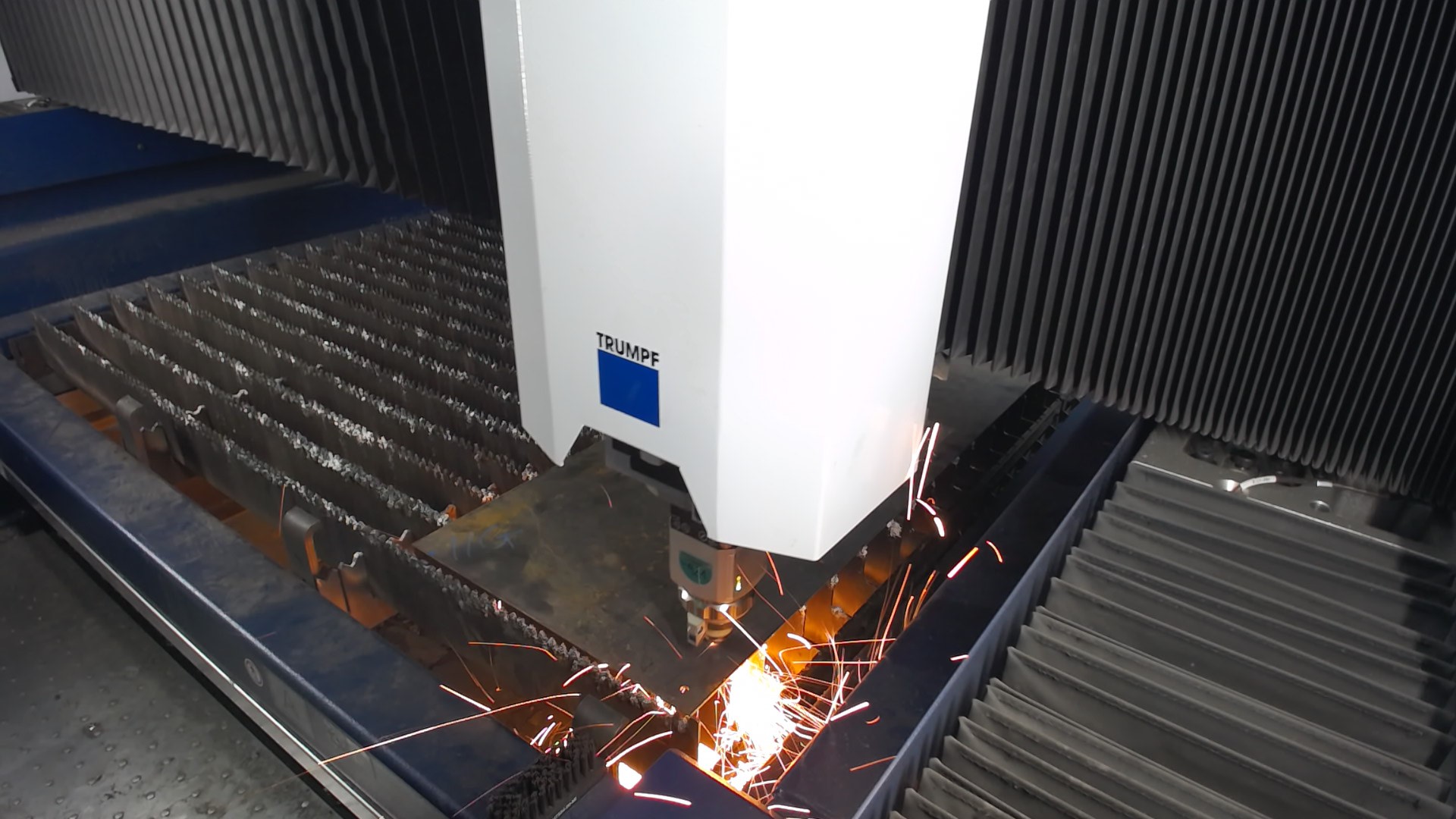

Precision Engineering

Precision is a hallmark of custom metal fabrication. Advanced techniques such as CNC machining and laser cutting enable the creation of components with exact specifications and tight tolerances. This precision engineering results in parts that function seamlessly within complex systems. At 4E Welding & Design Inc., precision is paramount, with state-of-the-art equipment used to achieve the highest levels of accuracy.

Precision engineering also reduces the risk of errors and defects in the final product. By using advanced technology and meticulous processes, fabricators can ensure that each component meets the desired specifications. This attention to detail is crucial in industries such as medical device manufacturing, where even minor deviations can have significant consequences.

Longevity

The combination of high-quality materials and precision engineering ensures that custom metal components are exceptionally durable. These components are designed to withstand harsh conditions and heavy use, leading to a longer lifespan. Investing in custom metal work means fewer replacements and repairs, ultimately saving businesses time and money.

Longevity is particularly important in industries such as construction and manufacturing, where equipment and components are subjected to constant stress and heavy use. Custom metal work provides the resilience needed to endure these conditions, reducing downtime and maintenance costs.

Cost-Effectiveness in the Long Run

Initial Investment vs. Longevity

While custom metal work may involve a higher initial investment, it offers significant long-term savings. The durability and quality of custom components mean they last longer and require less frequent replacement compared to standard products. This longevity translates to lower overall costs over the product's lifecycle.

For instance, in the manufacturing industry, investing in custom metal parts can lead to increased production efficiency and reduced operational costs. High-quality components reduce the risk of machinery breakdowns and the associated costs of repairs and downtime, providing a better return on investment over time.

Reduced Maintenance Costs

High-quality custom metal work also leads to reduced maintenance costs. The superior materials and precise fabrication result in components that are less prone to wear and tear. Businesses can benefit from fewer breakdowns and maintenance issues, which means less downtime and more productivity.

In industries such as oil and gas, where equipment reliability is critical, custom metal work can significantly reduce maintenance expenses. By using durable materials and precise engineering, companies can ensure that their equipment operates efficiently and reliably, minimizing the need for frequent maintenance and repairs.

Efficiency Gains

Custom solutions can significantly improve operational efficiency. By designing components that perfectly fit their intended applications, businesses can enhance the performance of their equipment and systems. This efficiency not only boosts productivity but also reduces energy consumption and operational costs.

Efficiency gains are particularly evident in industries such as logistics and transportation, where optimized components can lead to better fuel efficiency and reduced operational costs. Custom metal work allows for the creation of lightweight yet strong components, improving overall vehicle performance and reducing fuel consumption.

Improved Aesthetics and Branding

Design Flexibility

Custom metal work offers extensive design flexibility, allowing businesses to create aesthetically pleasing and unique components. Whether it’s for architectural elements, industrial machinery, or commercial fixtures, custom fabrication ensures that every piece not only functions well but also looks impressive. 4E Welding & Design Inc. excels in producing visually appealing custom metal work that enhances the overall aesthetic of any project.

Design flexibility is essential in industries such as retail and hospitality, where the appearance of fixtures and furniture plays a crucial role in attracting customers. Custom metal work enables businesses to create custom designs that reflect their brand identity and enhance the customer experience.

Brand Identity

Incorporating custom metal work into your business operations can also enhance your brand identity. Unique and high-quality metal components can set your business apart from competitors, showcasing your commitment to excellence and innovation. Custom metal elements can be designed to reflect your brand's style and values, creating a cohesive and professional appearance.

For example, custom metal signage and displays can make a significant impact on a business's branding efforts. These custom elements not only serve functional purposes but also reinforce the brand's image, creating a memorable impression on customers and clients.

Compliance with Industry Standards

Adherence to Regulations

Meeting industry-specific regulations and standards is crucial for any business. Custom metal work ensures that all components comply with relevant regulations, reducing the risk of non-compliance issues. Whether it’s adhering to safety standards or meeting environmental regulations, custom fabrication can help businesses stay compliant.

Compliance is particularly important in industries such as aerospace and medical device manufacturing, where stringent regulations govern the design and fabrication of components. Custom metal work ensures that all parts meet these regulatory requirements, ensuring safety and reliability.

Certifications and Quality Assurance

Certifications play a vital role in ensuring the quality and reliability of custom metal work. For example, 4E Welding & Design Inc. holds the Canadian Welding Bureau (CWB) certification for aluminum welding, a testament to their commitment to quality and excellence. This certification assures clients that all custom metal components are fabricated to the highest standards, providing peace of mind and confidence in the final product.

Quality assurance processes, such as regular inspections and testing, further ensure that custom metal components meet the required standards. These processes help identify and address any potential issues before they affect the final product, ensuring consistent quality and reliability.

Examples of Custom Metal Work Applications

Industrial Applications

Custom metal work is widely used in industrial settings for the fabrication of specialized machinery, components, and structures. From conveyor systems to custom machine parts, the ability to tailor solutions to specific industrial needs enhances efficiency and productivity.

In the manufacturing sector, custom metal work can be used to create parts and components that optimize production processes. For example, custom fixtures and tooling can improve the efficiency of assembly lines, reducing production times and increasing output.

Commercial Applications

In commercial businesses, custom metal work can be used to create unique fixtures, displays, and furniture. These custom pieces not only serve functional purposes but also contribute to the aesthetic appeal of commercial spaces, attracting customers and enhancing the brand image.

Custom metal work is particularly valuable in the retail industry, where custom displays and fixtures can create a unique shopping experience. These elements not only showcase products effectively but also reinforce the brand's identity, creating a cohesive and engaging retail environment.

Architectural Applications

Architectural designs often require custom metal work to achieve specific aesthetic and structural goals. Custom metal components can be used in building facades, staircases, railings, and more, adding a unique and durable element to architectural projects.

In architecture, custom metal work allows for the creation of innovative and eye-catching designs that enhance the visual appeal of buildings. From intricate metalwork in staircases to bold and modern facades, custom metal elements can transform architectural projects, making them stand out.

Conclusion

Investing in custom metal work offers numerous benefits for businesses, from tailored solutions and enhanced durability to cost-effectiveness and improved aesthetics. By partnering with a professional metal fabrication shop like 4E Welding & Design Inc., businesses can ensure they receive high-quality, custom-made components that meet their specific needs and exceed industry standards. Consider custom metal work for your next project and experience the long-term advantages it brings to your business operations. Custom metal work is not just an investment in quality and efficiency but also a commitment to innovation and excellence, positioning your business for success in a competitive market.